Vertical Split Tube Furnace

Features of the Vertical Split Tube Furnace:

Vertical Orientation: Designed in a vertical configuration, ideal for applications requiring controlled upward or downward temperature gradients.

Split Tube Design: Features a split tube arrangement for convenient loading and unloading of samples or materials.

High Temperature Capability: Capable of achieving high temperatures suitable for sintering, annealing, and materials research.

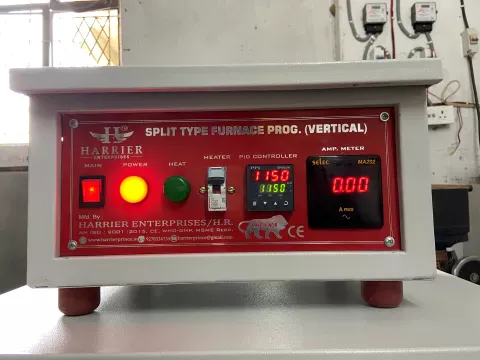

Digital Temperature Controller: Equipped with a digital controller for precise temperature management and programming.

Safety Features: Includes over-temperature protection and safety interlocks to ensure secure operation.

The Vertical Split Tube Furnace is a versatile thermal processing solution designed for applications that benefit from a vertical heating arrangement. This configuration allows for controlled temperature gradients along the vertical axis, making it suitable for processes such as crystal growth, thermal decomposition, and other experiments requiring precise thermal conditions. The split tube design facilitates easy loading and unloading of samples, enhancing operational efficiency in laboratory and industrial settings. With its capability to achieve high temperatures necessary for advanced heat treatment processes, the furnace ensures reliable performance in sintering ceramics, annealing metals, and conducting materials research. A digital temperature controller enables precise temperature setting and monitoring, ensuring consistent and reproducible experimental results. Safety features such as over-temperature protection and safety interlocks are incorporated to prevent overheating and maintain safe operation during high-temperature processes. Built with durable materials and advanced insulation, the Vertical Split Tube Furnace is engineered for longevity and reliability, making it an indispensable tool for researchers and engineers seeking efficient thermal processing solutions in vertical orientations.