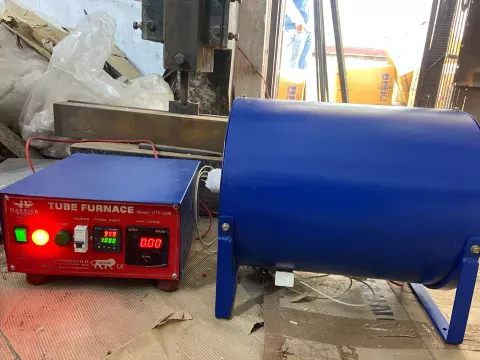

Cylindrical Tube Furnace

Features of the Cylindrical Tube Furnace:

Cylindrical Design: Characterized by its cylindrical heating chamber, which accommodates longer samples or materials.

High Temperature Capability: Capable of achieving high temperatures suitable for sintering, annealing, and materials research.

Uniform Heating: Ensures even distribution of heat along the length of the tube, critical for consistent experimental results.

Digital Temperature Controller: Equipped with a digital controller for precise temperature management and stability.

Versatility: Suitable for a wide range of applications including synthesis, decomposition, and heat treatment processes.

The cylindrical tube furnace is a versatile and efficient heating solution designed to meet the demanding requirements of thermal processing in both laboratory and industrial environments. Its distinctive cylindrical design allows for the accommodation of longer samples or materials, making it ideal for applications that involve continuous or extended thermal treatments. Capable of reaching high temperatures necessary for processes such as sintering ceramics, annealing metals, and conducting materials research, the furnace ensures reliable performance and consistent results. Equipped with a digital temperature controller, operators can precisely set and monitor temperature profiles, ensuring optimal conditions for experimental protocols or production processes. Uniform heating along the length of the tube is guaranteed, promoting reproducibility and accuracy in experimental outcomes batch after batch. Whether used for synthesis of new materials, thermal decomposition studies, or advanced heat treatments, the cylindrical tube furnace stands as a reliable and indispensable tool for researchers and engineers seeking precise thermal control and consistent performance in diverse thermal processing applications.